FlexSim + Digital Twin

In need of a digital twin for your manufacturing, material handling, supply chain, or healthcare system? We can do that! FlexSim is commercial, off-the-shelf 3D simulation modeling software—ready out-of-the-box to help you accomplish your digital twin strategies. Not to mention world-class training and support, including model-building services to assist with developing an accurate digital model of your operations.

Try FlexSim for free today and see how we can be your engine to optimize and improve.

Why use FlexSim for your digital twin?

FlexSim is the most capable and easy-to-use simulation modeling and analysis software. It’s as simple as that. FlexSim is ready out-of-the-box to help you create better, more accurate simulation models in less time. A digital model is crucial to your digital twin—so go with the best simulation modeling software.

Learn more about what makes FlexSim so easy to use.

Advanced features to handle any application

FlexSim is packed with advanced features and capabilities to handle any digital twin application.

- FlexSim’s open architecture means we make it much easier to develop a model that auto-builds from your data. Don’t believe us? Try to auto-build a model from raw input data using any other simulation package and experience the difference yourself.

- FlexSim provides robust database connectivity features, making it simple to import and export the data that your digital twin will process.

- FlexSim has advanced communication features, including a RESTful HTTPS API, our Webserver interface, and limitless extensibility through DLLs and our Module SDK.

- FlexSim supports AI and machine learning, including a tool to train reinforcement learning algorithms.

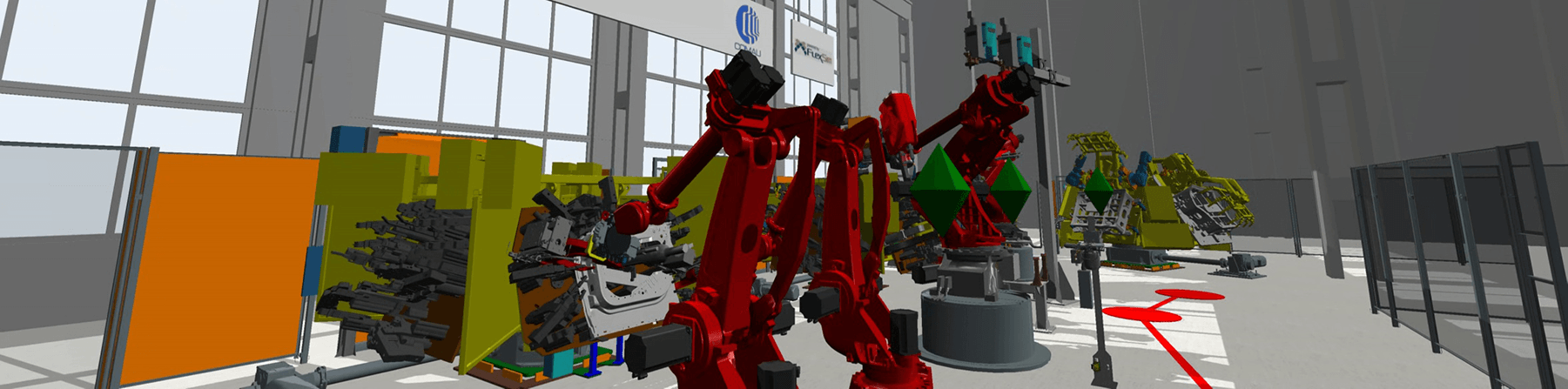

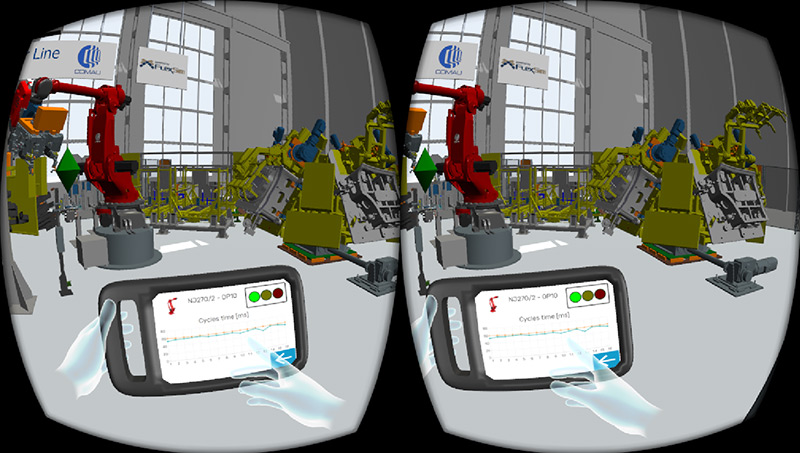

- FlexSim is VR-enabled, with a simple one-click option to view a simulation model in virtual reality with touch controls.

Keep data and expertise in-house

FlexSim is designed to be easy to use, which means you can build your digital twin applications internally. Your competitive competencies, knowledge, and ownership of your digital twin can stay in-house—and avoid expensive outside consultants. Your data will also remain on-premises for added security and cost savings.

Real FlexSim digital twin projects

[After presenting our model], one of the first things out of the site manager’s mouth was, “I love the fact that the model tells you where to put each sling in the warehouse. I want you to figure out a way to use FlexSim so my guys on the floor can access that [information] and have it tell them where to put the sling.” … [The digital twin] does everything that the model was designed to do, and then export it into a user-friendly format for a handheld scanner to be able to read into those algorithms.

We wanted to widen the total output of the factory, the assembly lines and equipment. There’s a physical entity [the factory], a digital entity [the FlexSim model], and a data repository… and we wanted to create the connectivity between them, aggregate the data, and make the work a lot smarter than it was before.

Frequently Asked Questions

-

At its core, a digital twin is a virtual representation of a physical process. FlexSim’s core competency is creating 3D models that represent the look and behavior of your existing system. These models simulate how the actual system would respond using different inputs and layouts. This is the most basic implementation of a digital twin—to improve or answer questions about your system.

-

Yes, a FlexSim model can automatically pull in data at regular (or even real-time) intervals and run simulations. This is a more advanced digital twin application, and the possibilities are endless. FlexSim models can be used to:

- Automatically send recommendations to manufacturing or warehouse management software

- Train reinforcement learning algorithms

- Feed simulation data into a traditional AI algorithm (e.g., supervised learning, neural nets)

- And much more!