Supply Chain Simulation

FlexSim can help you analyze and improve operations across the supply chain, including manufacturing, warehousing, material handling, and logistics.

Why supply chain simulation?

Why is simulation a good choice for analyzing supply chains? Because modern supply chains are so large and complex, it becomes difficult (or impossible) to predict the impact of change using other methods. There are three significant challenges to supply chain analysis:

- Real-world variability

- Complex interdependencies

- Problems usually develop over time

Tools like spreadsheets cannot accurately consider all three elements, so you’re not getting a complete picture. With simulation modeling, you can develop a digital twin of the real-world system—so changes you make in the model will lead to accurate predictions in the real world. Think of simulation as a risk management lab, a virtual environment where you can get fast, precise analysis to make better decisions.

With supply chain simulation, you can:

- Optimize existing processes to reduce occurrences of stockouts and overstocks

- Test and measure the potential impact of new routes, equipment, and personnel

- Validate future project plans by making sure they behave as intended in a model

- and much more!

Supply Chain Model Development

Process Flow

Our innovative logic-building tool is excellent for building supply chain simulation models. Process Flow replaces nearly all computer code with pre-built activity blocks to lay out the logic as you “flowchart” your system’s behavior. It’s an intuitive way to organize and define your processes, and it scales well as the model becomes more extensive or detailed.

Watching a simulation run, you’ll see two levels of validation. You have a 3D visualization where products and people move around accurately. And you have a logical view where you can see each step in your supply chain process.

GIS Module

The Geographic Information System (GIS) Module brings your model to life with visualized travel and up-to-date routes over land, air, and sea. Time and distance are critical in supply chains, inter-logistics, and transportation systems—and this tool will help you model them accurately. The GIS Module even comes pre-configured to route paths across road networks worldwide.

Supply Chain Model Analysis

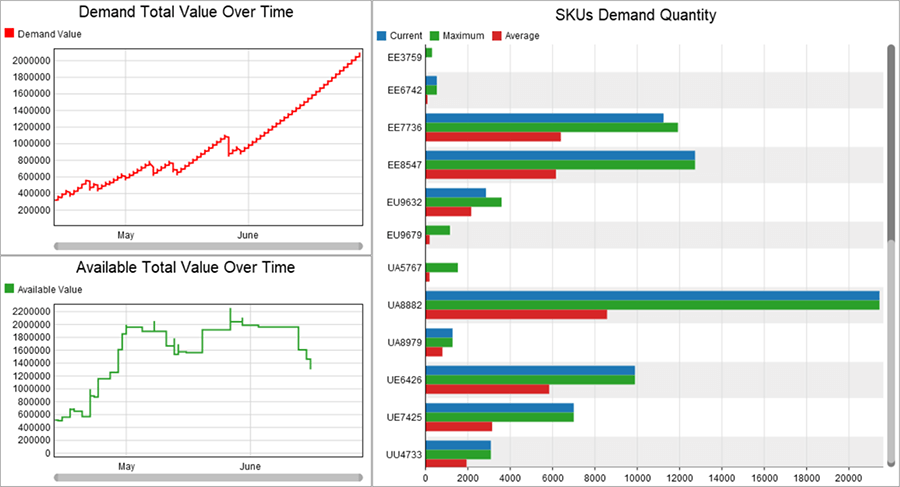

Dashboards

FlexSim comes with dozens of pre-built charts and graphs to help you visualize the data from your simulation model. Watch the data accumulate in real-time, or export the data to your favorite application for further analysis. There are also powerful tools like the Stats Collector to gather and display highly customized data.

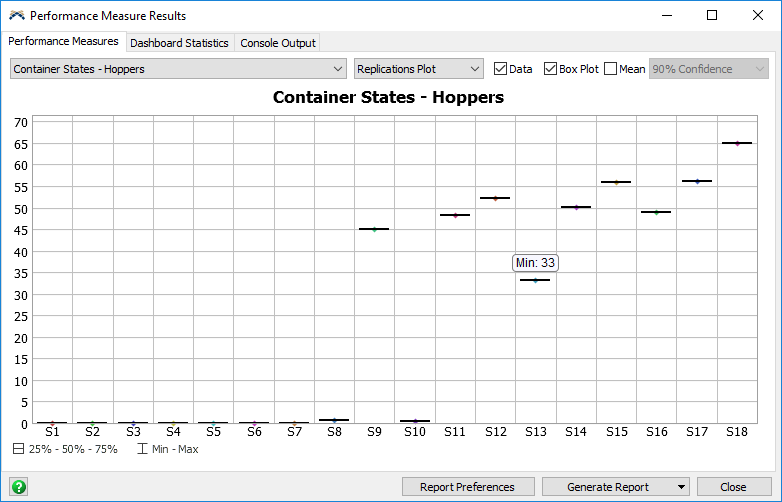

Experiments

The Experimenter tool is FlexSim’s scenario manager. Create, manage, and run different scenarios, then compare the results with our onboard analysis tools and reporting. FlexSim is a multi-core application, so simulation replications are spread across your CPU cores to run experiments in a fraction of the time.

Optimization

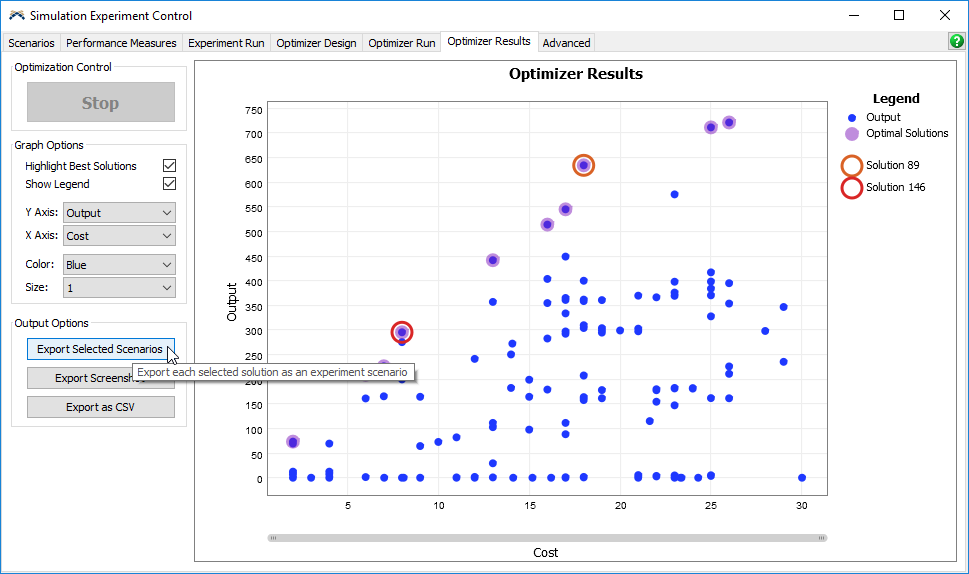

FlexSim is fully integrated with the OptQuest optimization engine. This feature upgrades your experiments by allowing you to set variables and constraints on your model to search for the best solutions. The Optimizer has an intuitive interface to choose model parameters and performance measures and includes advanced features such as true multi-objective search.

Case Study

Adapting to Change

What do you do when a plant closure forces production volume to different locations? Dallas-based consulting firm Quadrillion helped a client face this reality and chose to use simulation as a strategic planning tool. Learn more about their simulation model and how they answered critical questions about a large manufacturing supply chain.