It’s already used in industry, and it can definitely benefit modelers

Have you seen the new commercial for Samsung’s Gear VR? It wasn’t what I’d expect from a virtual reality device—because we barely even saw Samsung’s new virtual reality headset. Instead, the commercial was careful to stay away from the geeky, unwieldy look the technology had in a recent Time Magazine cover. Viewers see NBA superstar LeBron James and a bunch of average Joes and Janes. They go about their daily routines while lip syncing to a popular 90’s rap hit.

The message is clear: virtual reality isn’t just a toy for video gamers.

Industry has already caught on to virtual reality, and so has FlexSim. We’re pleased to announce our support for the oft-hyped Oculus Rift. Once the popular virtual reality device sees a consumer release around March (or if you already own one of the Development Kits), you’ll be able to check a box for “VR Mode” and enjoy virtual tours of simulation runs in FlexSim.

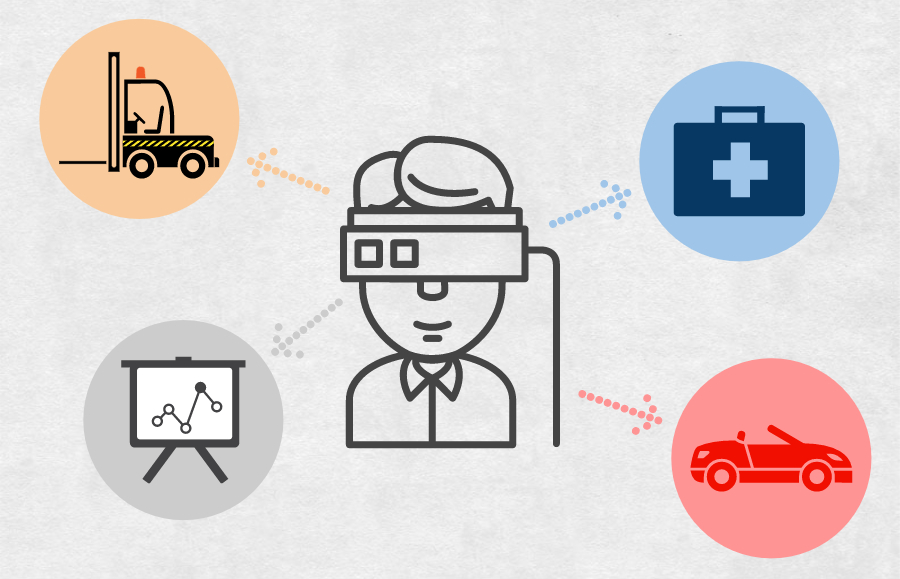

Why would you care about virtual reality in a simulation model? Well, this technology is already used and accepted by companies like Ford, BAE Systems, and Audi to benefit different aspects of their operations. For simulation modeling, there are a few key positives that you just might want to take advantage of.

Avoid costly design mistakes

The early returns here are promising. Are you interested in catching design flaws that would have otherwise been missed, resulting in big cost savings? Ford is already doing this with their vehicles, and it’s helping them be more agile and responsive to problems. Their VR specialist, Elizabeth Baron, said, “In the past we would have had to build a physical model to see how change would impact our design.”

It doesn’t take a big leap to see how system design could have a similar impact. One FlexSim user has a 3D Cave that engineers use to validate processes and layouts. This allows them to avoid costly design mistakes. They explained their virtual reality needs to us: “Unfortunately due to cost and availability, we are not able to use [the 3D Cave] as often as we would like. Oculus Rift could serve as a powerful alternative to the significantly more expensive 3D Cave environment.” That wait is now over—FlexSim users can now enjoy visualizing with this cheaper device.

Share a new level of understanding

Virtual reality also offers engineers the gift of perspective and immersion. A FlexSim user told us, “The ability to work with immersive 3D factories opens up very interesting possibilities in terms of new facility/process development.”

Last year, we saw several companies use FlexSim as a visual tool to sell projects to potential clients. Even in early stages of a project, they were able to paint a compelling picture of future value. The short videos they made of their simulation models brought projects to life before they even got off the ground.

What they also did was get people talking. Talking about the system, about something they never noticed before, and about a new idea they just had. Virtual reality adds a deeper dimension to this experience. It was amazing to watch seasoned professionals put on the Oculus Rift and walk through a FlexSim model. Most of these educators and engineers have seen thousands of models in their careers. They were all giddy and excited as they ventured into an unfamiliar virtual world.

The Experience. That’s what Samsung’s commercial was really about, and it’s the best chance virtual reality has to stick around in the mainstream. As for industry, it looks like many companies are already invested enough to keep the technology, and its benefits, around for years to come. Whenever you’re ready for a fresh, educational perspective on your simulation models, grab an Oculus Rift and experience virtual reality through FlexSim.