3D Simulation Modeling and Analysis Software

Understand and improve any system or process. FlexSim will help you transform your existing data into accurate predictions. Capterra users can try this simulation software free of charge—just sign up for a free account today!

Here’s what people are saying about FlexSim

“A necessity for process improvement”

FlexSim has been monumental in achieving process improvement goals. It really gets the faculty on board when they can see themselves walking around. It’s visual and helps the user understand their processes and systems so that they can improve. We’ve saved hundreds of thousands in preventable costs by changing processes and staffing levels based on future patient volumes.

![]()

“Extraordinary tool and support”

Versatility. There is almost no scenario that we haven’t been able to support… But it goes beyond the tool; the can-do attitude and creativity of the FlexSim consultants is critical as well. I can’t say enough good things about their willingness to find ways to model the variety of scenarios we encounter. FlexSim has something for both sides of the brain—visuals are spectacular, almost beautiful. Rigorous performance quantification of complex systems completes the picture.

![]()

“FlexSim simulation software gives great analytical capability”

I have seen FlexSim used at each of my employers, and it has been an analytical powerhouse for identifying problems and assessing solutions.

![]()

“Great software with that lives up to its name of 'flex'ible and easy to use”

Can apply to many different processes or types of operations. Great for showing manual and automation processes that work together. Easy to use and train new users on the software. The flexibility of the software has allowed me to show automated processes with manual processes, part movement, and part flow all at the same time. Ability to show how things interrelate on a larger scale.

![]()

“Best simulation software ever!”

I’m working in batch process production where each type of product van run on each line—main use of FlexSim is to get the optimum sequence for each line to run maximum performance. We [also] use FlexSim to optimize and calculate the logistics of the products in and out the production… The different ways of designing a scenario, in combination with the variables and inputs, are just great. You have the typical drag and drop, then the flow chart and even code for the super special stuff. And best of all these can be combined!

![]()

“Awesome software!”

Infinite possibilities, awesome graphical interface, huge flexibility, easy to apply to an industrial environment, active and professional community on the forum, [and] Add-Ons.

![]()

“Simulation made easy and intuitive with FlexSim”

Not only does FlexSim have great 3D graphics potential compared to other software applications in the market, but also its simplicity and intuitive modeling structure gives it an edge from the rest.

![]()

“Great sim tool”

I like FlexSim’s flexibility in modeling material handling processes of all kinds and use experimentation to rapidly compare multiple scenarios. Its intuitive to use and easy to run.

![]()

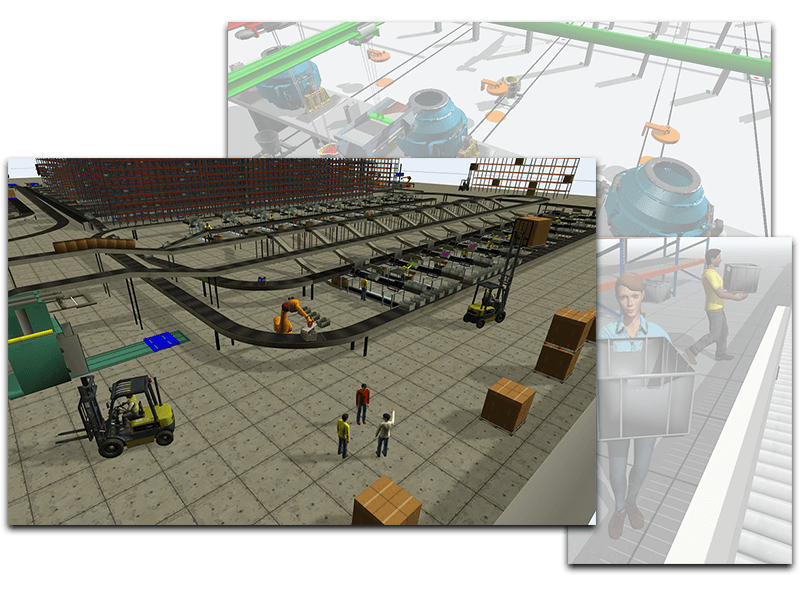

End-to-End Process Improvement

Risk-Free Virtual Environment

Build a dynamic computer model of your system and test “what if” scenarios to see what works in the real world. Learn important lessons in a simulation first!

Industry 4.0 + Digital Twin

FlexSim is already in use around the world as a digital twin in advanced production systems. Our open architecture, database connectivity, and powerful modeling tools make it possible.

Rich Capability for Every Industry

FlexSim has a deep, robust feature set that covers manufacturing, warehousing, healthcare, supply chain, and many other critical business processes.

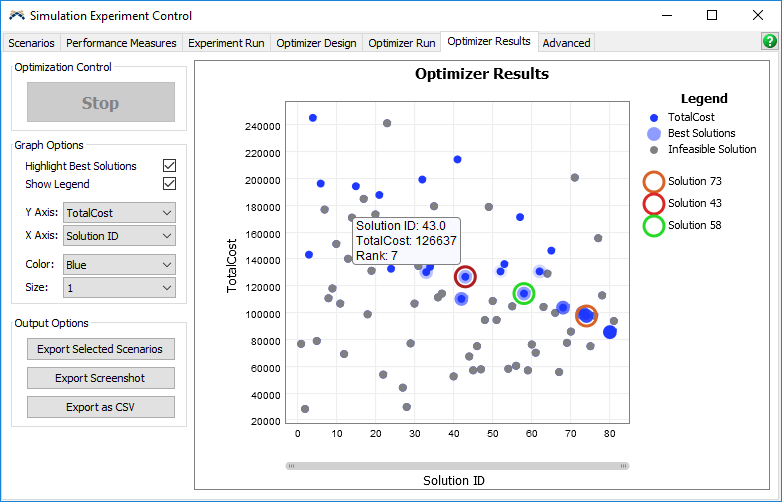

Analysis Beyond Spreadsheets

Improve on older, static analysis! FlexSim accounts for time, space, variability, and the complex relationships within your system.

3D Visuals + VR

FlexSim’s 3D environment and stunning visuals lets you really see what’s happening. Or put on a VR headset and take the simulation experience to the next level.