The United States Court of Appeals for the Federal Circuit affirmed the judgment of the District Court of Utah in favor of FlexSim Software Products, Inc. and against Simio LLC, ending the patent infringement litigation initiated more than four years ago and sustaining FlexSim’s long-held belief that Simio’s asserted patent rights were invalid.

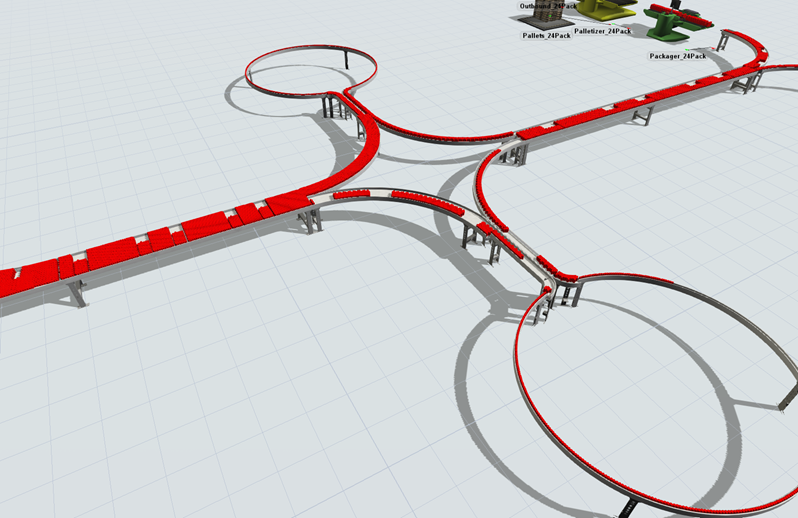

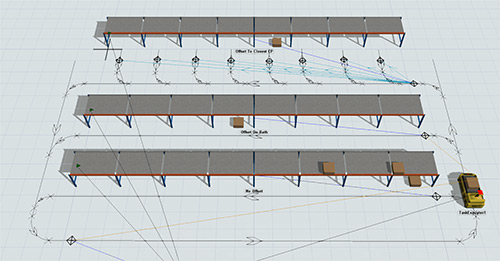

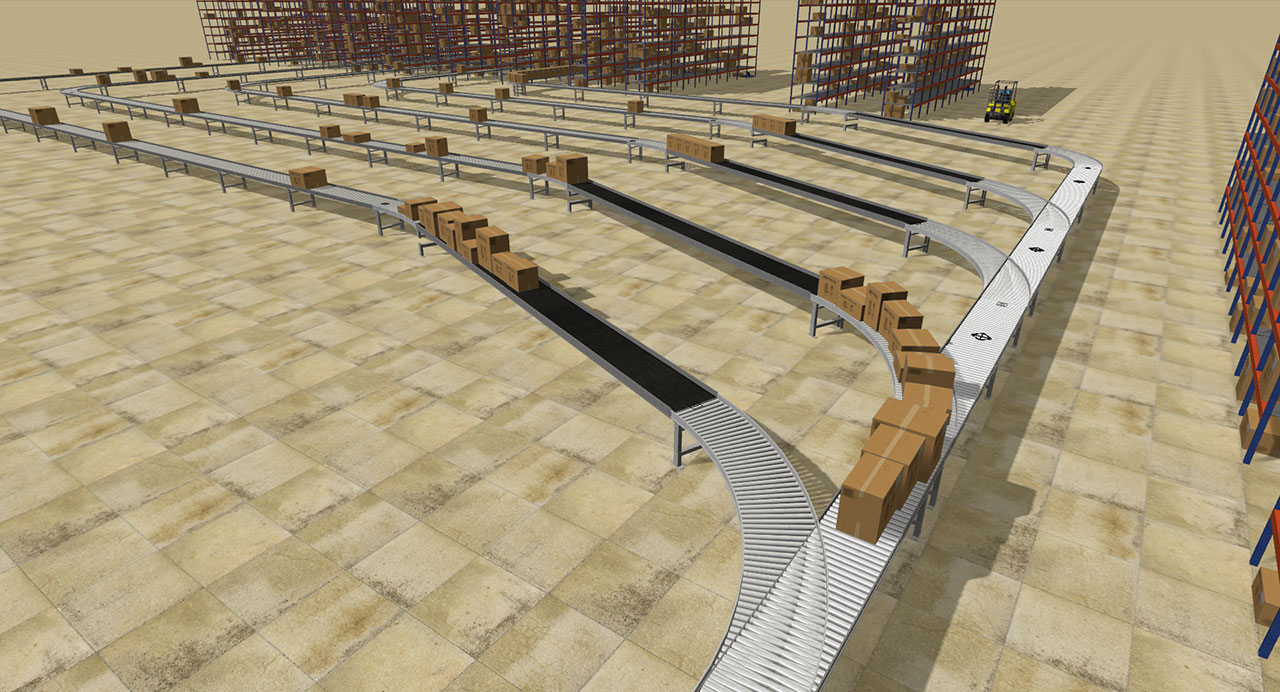

This release is another huge step forward for FlexSim’s AGV module, both in its improvements to model more warehousing situation and in its new ability to model train and rail systems. FlexSim 2020 Update 1 also streamlines libraries with new pop-out menus, introduces a simpler and more friendly Statistics Collector, and much more.

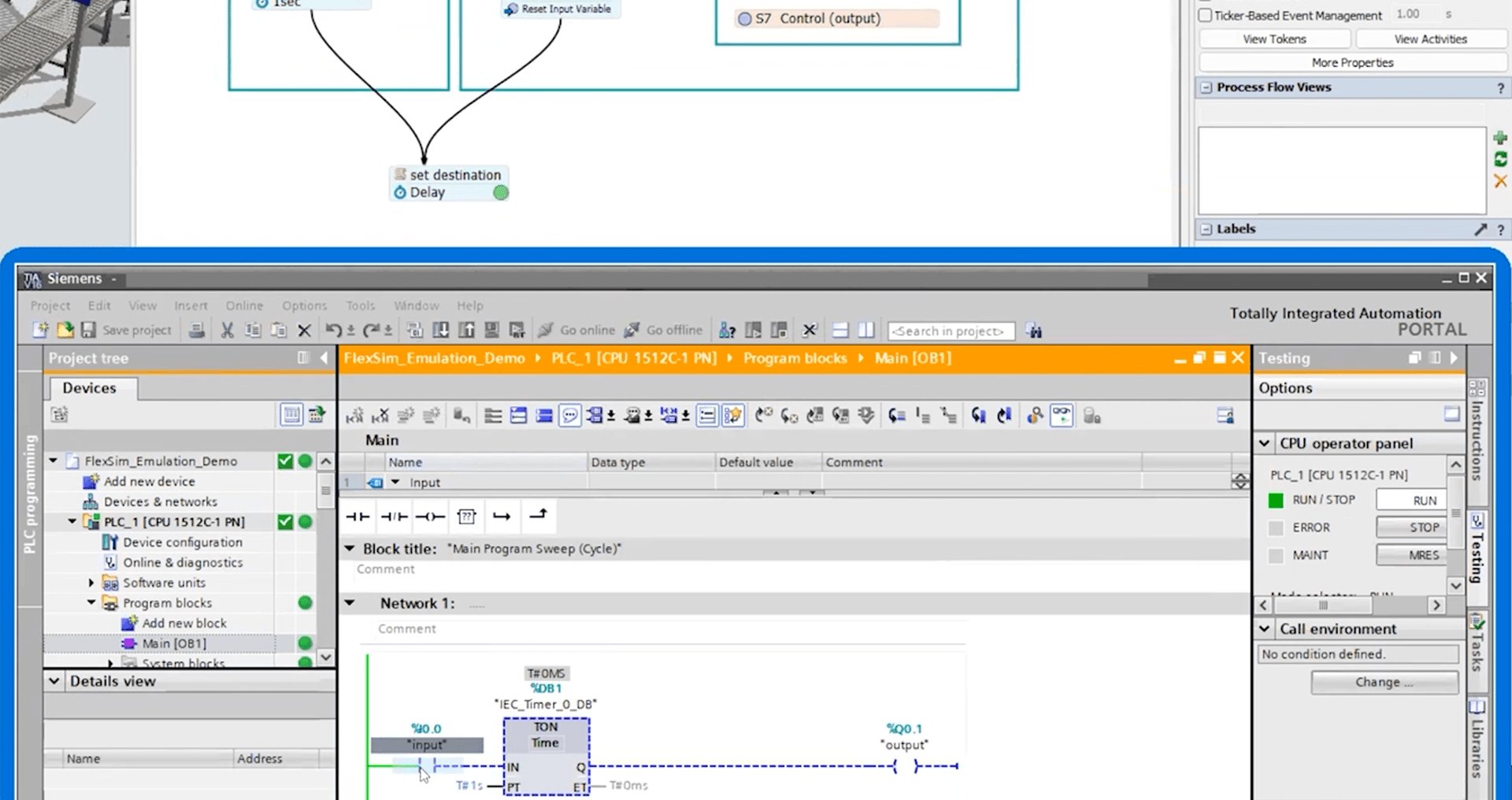

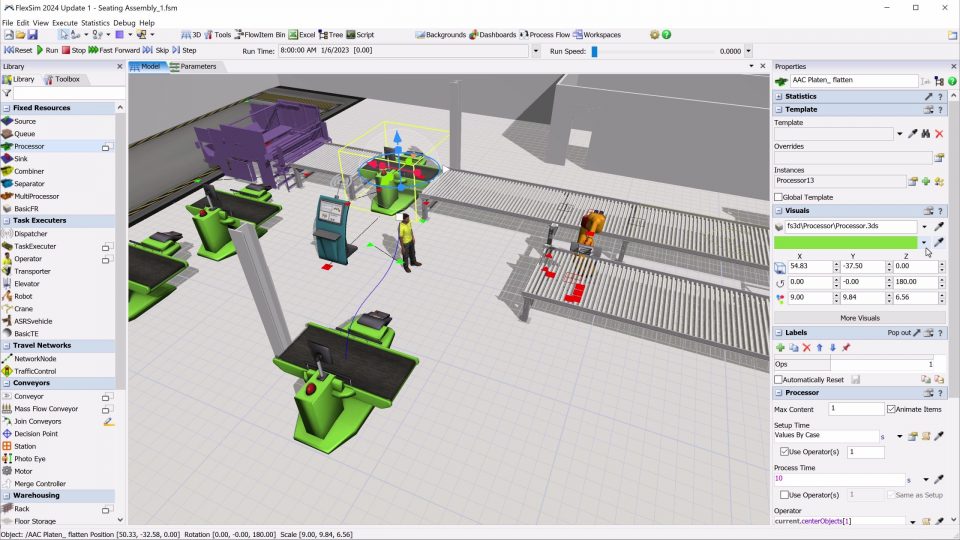

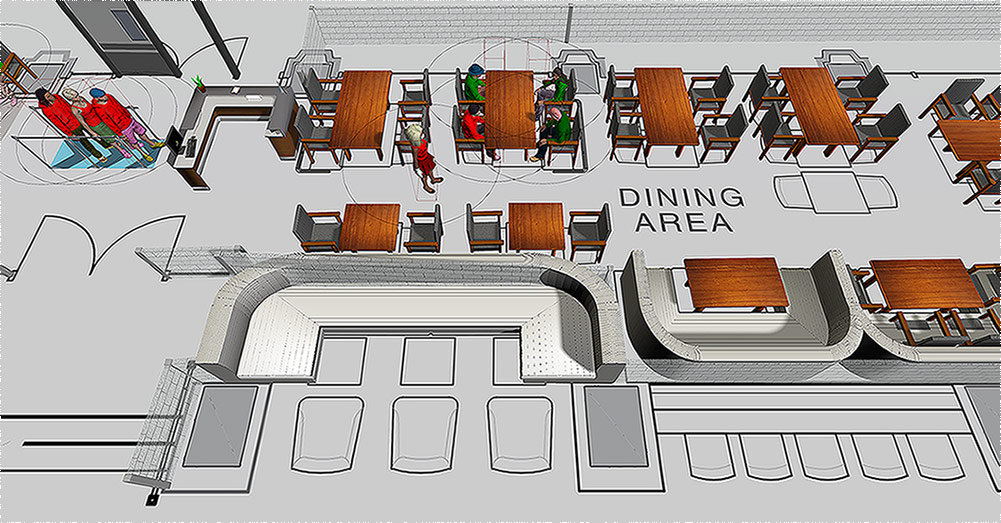

This release features improvements and additions throughout the software, from visuals to emulation to people-based modeling and beyond. FlexSim 2020 adds support for the OPC UA protocol when making PLC connections, adds numerous updates and additions for people-based modeling, new lighting effects, and much more.

FlexSim was recently featured in a virtual reality social innovation competition that aimed to solve existing social and environmental issues in Hong Kong. Students were trained to use the simulation software to create their own 3D models and judged on their design, innovations, and overall presentation.

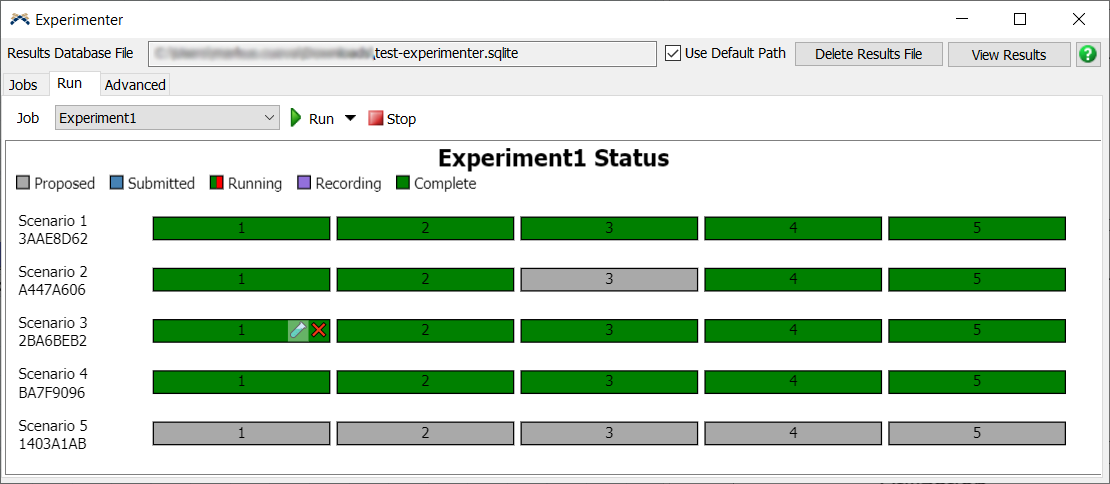

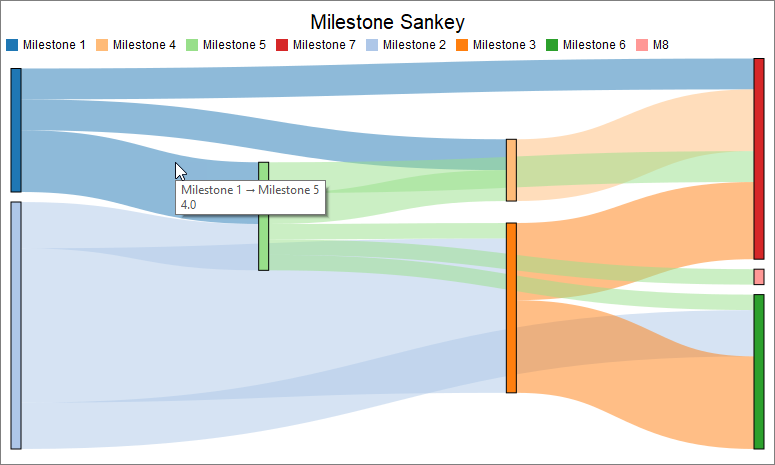

FlexSim 2018 Update 2 provides the ability to use distributed CPUs in the Experimenter and Optimizer—either using Cloud computing, your own computers in a local network, or both. This means that you can significantly reduce the time to run replications in your FlexSim experiments. Plus reversible conveyors, Sankey diagrams, and much more.

Takes a long time (more than a few minutes) to run a single replication

Contains a very large number of replications

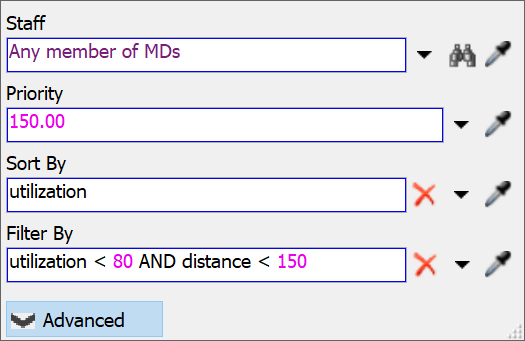

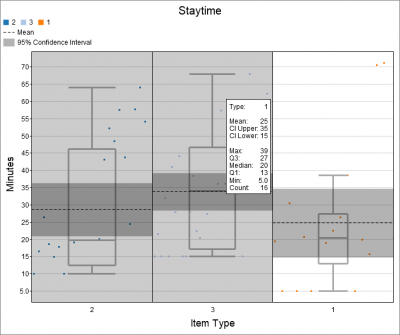

FlexSim 2017 Update 2 brings an important change to how FlexSim collects and displays data. This data and analysis change has two major advantages. First, it gives you fine-tuned control to gather exactly the data you’re looking for. Second, it gives direct access to the raw data; FlexSim now behaves similarly to popular spreadsheet and charting applications, where the data comes first and then any number of charts and graphs can be created from the data.

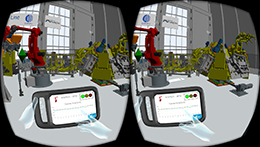

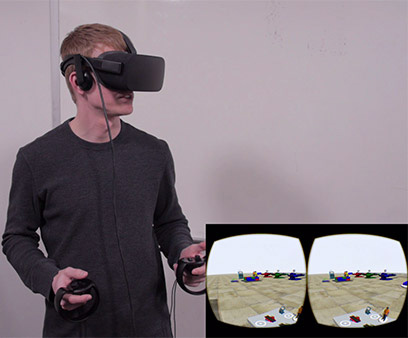

This update to FlexSim 2017 takes FlexSim’s virtual reality capabilities to the next level. It starts with the Oculus Touch hand controllers. With their natural gestures and finger movements, this technology will let you experience a FlexSim model like never before. This update also includes expanded ease-of-use features to save time building simulation models, improvements to SQL in FlexSim, and much more.

A lot of the development in FlexSim 2017 centered around FlexScript, our powerful and easy-to-use scripting language. We believe the end result is a more cohesive and intuitive experience when you choose to use FlexScript in a model—check out our recent blog post for more details, and read on for more information on the great new features and improvements in this release.

FlexSim was recently featured in the European Mensa Annual Gathering (EMAG) in Poland. FlexSim specialist, Dawid Dabal, spoke on FlexSim simulation software and its dynamic technology in his presentation, and how ‘smart technology’, such as simulation, can benefit anyone seeking solutions to complex problems.

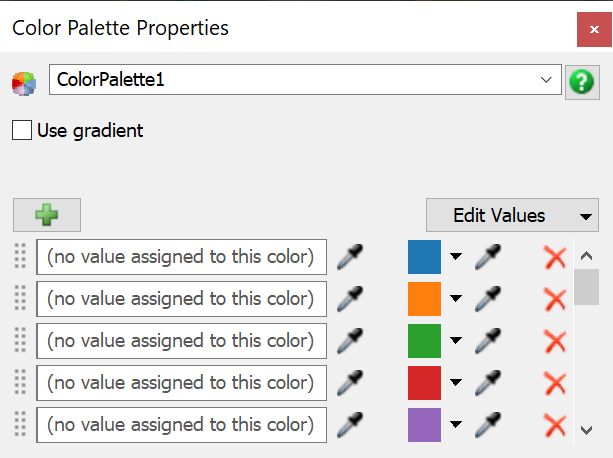

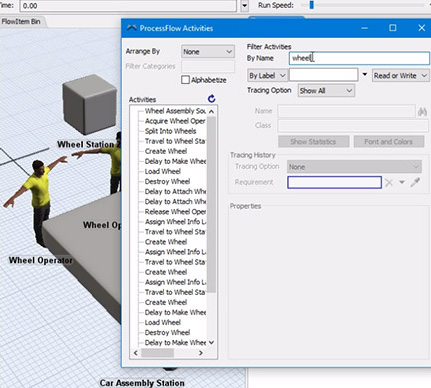

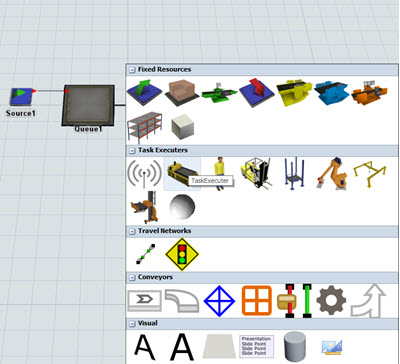

FlexSim 2016 Update 2 contains a handful of key user interface improvements that will streamline and enhance the modeling experience, including the all-new Quick Library interface. We've also added three new Process Flow activities (Split, Synchronize, and Join) to help with coordinating processes—you can use these coordination activities to selectively synchronize several events, allowing you to properly model these complex systems with less time and effort than ever before.

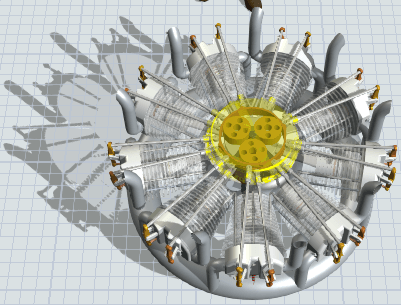

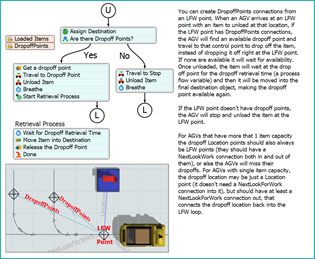

This version of FlexSim introduces a stable, long-term release of our simulation modeling software that will continue to receive bug fixes for several releases. It also introduces templates for Process Flow. These pre-made standard objects—along with two incredibly powerful AGV templates—can be customized using activities in Process Flow, as opposed to a combination of triggers and other methods. The AGV templates are game changers, vastly reducing the time you need to spend developing the logic for AGV models.

Politecnico di Torino has finalized an agreement with FlexSim Software Products, Inc. to provide 3D simulation modeling software to the university. Students and professors will receive the same industry-standard software used by companies worldwide in the manufacturing, material handling, healthcare, warehousing, mining, and supply chain sectors.

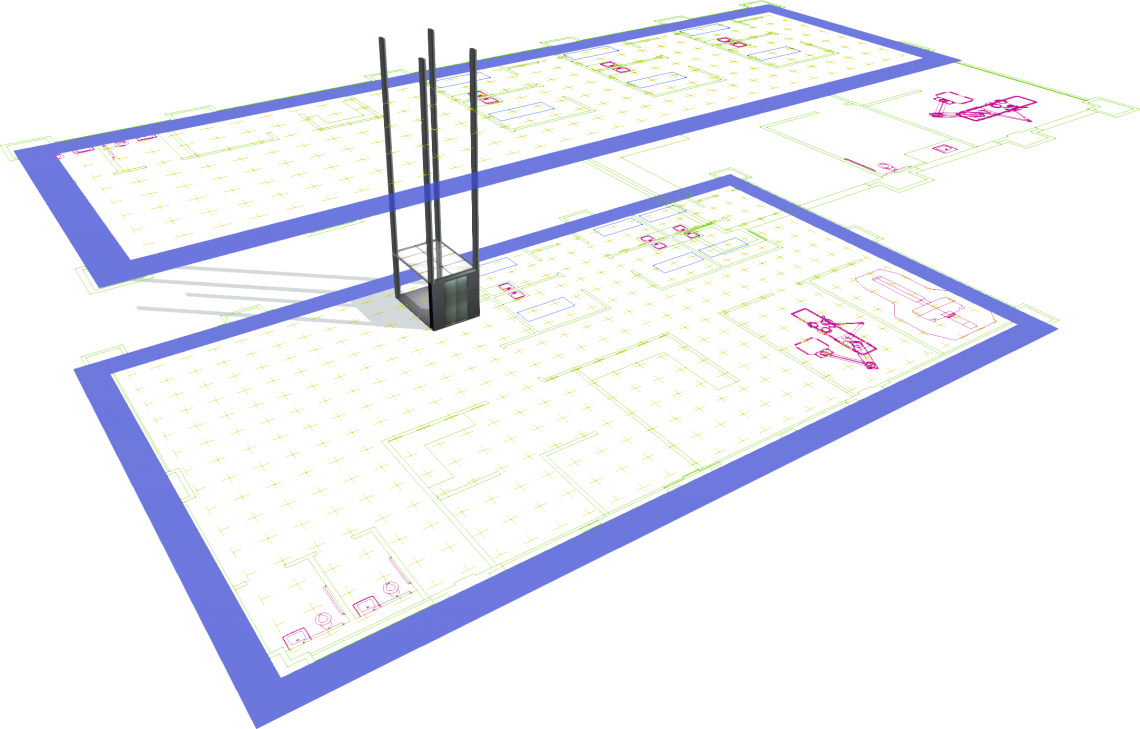

FlexSim 7.3 adds several features, including AutoSave, that will make model building more convenient. This latest version also builds on the visual improvements in versions 7 and 7.1 to cement FlexSim as the industry leader in 3D simulation software. Check out the new Toolbox, the Model Floor object, and much more.

FlexSim's truck haulage simulation application will be used by mining industry leader RPM in their HAULSIM product, the first industry-specific haulage simulation solution. It is the most powerful tool available for modeling, analyzing, visualizing, and optimizing a haulage network, providing confidence and accuracy in mine plans. “We are excited to be working with RPM in mining,” said FlexSim CEO Bill Nordgren.

The biggest change in 7.1.0 is to the area of analytics, which have been fully assimilated into the dashboard interface. The information that was previously found in FlexSim Chart and the Statistics tab of an object’s properties window can now be accessed in one central location, making dashboards a “one stop shop” for real-time data and analysis.

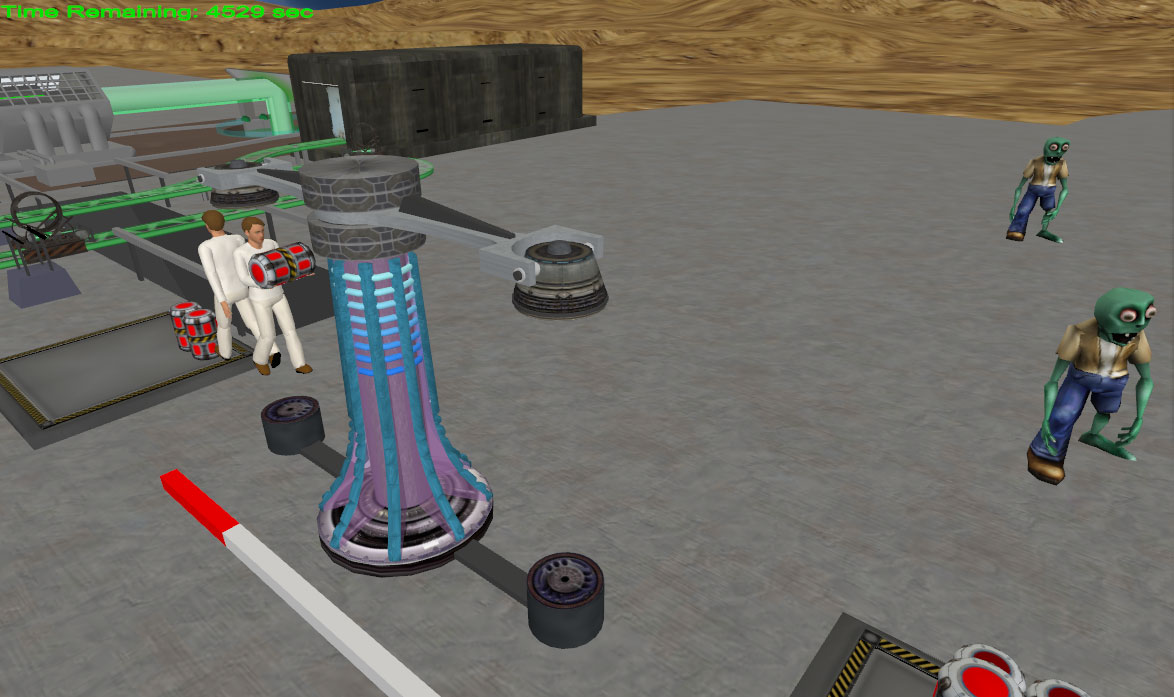

In the Summer of 2013, students in and around the Chesapeake area had the opportunity to participate in the STEM Zombie Challenge at their local library. The event, which was sponsored by local organizations and supported by FlexSim, encouraged junior high and high school-aged students to work together, learn, and have fun while playing a game that was built into a FlexSim model.