FlexSim Involved in Advancements with Industry 4.0 Technologies

New digital twin and exoskeleton simulation projects developed with Comau showcase FlexSim’s capabilities in Industry 4.0

FlexSim Software Products, June 25, 2018 — FlexSim is excited to debut two advancements in simulation technology. The projects, developed with FlexSim’s partner in Italy, Flexcon s.r.l. in conjunction with Comau, have exciting applications in the ever-expanding world of Industry 4.0.

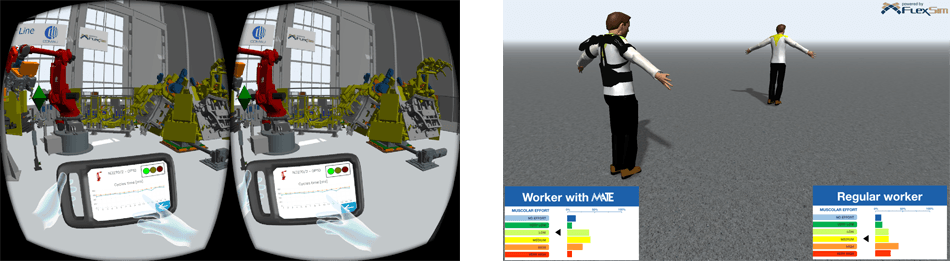

The digital twin project was developed as a virtual reality application that integrates with other software applications. It’s used to provide real-time data displays in the fast-moving automotive sector. Visitors will be immersed in a production line and “move” within it, monitoring key process and machinery parameters (e.g. through a continuous check of insights such as vibration, temperature and others). The digital dashboard will also identify issues which could create bottlenecks or breakdowns.

FlexSim’s exoskeleton simulation project integrates FlexSim with human motion capture technology to allow the simulation of a human exoskeleton. The simulation shows how effective the exoskeleton is in aiding human operators during manufacturing-related tasks, in terms of ergonomy and muscular effort.

The benefits of these technologies include:

- Quickly verify production parameters at any stage of the manufacturing process.

- Virtual simulation and line behavior testing results in higher productivity, better quality, faster time-to-market and lower costs.

- Sensorized exoskeleton helps improve ergonomics in the workplace by analyzing movements and activities with analytics and parameter comparisons.

About FlexSim

FlexSim Software Products, Inc., is an industry leader in simulation modeling software. The company is committed to developing products that help consumers solve problems, save time and money, and reduce risk.